Idle Reporting/Reduction

Fuel Management/Reporting and Idle Management Reporting Save 5-15% Annually on Fuel Costs

3C Telemetry provides you with all the tools necessary to collect Realtime Data for today and historical data for tomorrow.

Fuel consumption is a critical concern in the rail industry, accounting for a substantial portion of operational costs. Locomotives have a significant appetite for fuel, with consumption rates ranging from 3-5 gallons per hour while idling to nearly 200 gallons per hour for larger locomotive engine sizes at higher-notch settings. A rough diesel price of $4 per gallon can cost a locomotive over $800 in fuel per hour of operation.

Across a fleet of a dozen or hundreds of locomotives, this could mean substantial savings in fuel used annually which means making even minor efficiency improvements can significantly impact the overall profitability of a railway and its ability to reach its sustainability target helping to reduce locomotive idling and allowing customers to achieve outstanding fuel savings, while simultaneously reducing emissions.

Our technology and fuel reports provide alerts about Excess Idling and Fuel Levels. Idle Monitoring/Reporting can save your railroad at least 5-15% annually on fuel.

Emission Reduction… As Easy as 1, 2…3C Telemetry

per tree to 31.5 kg CO2 per tree. To compensate 1 tonne of CO2, 31 to 46 trees are needed.

One example of a single Class 1 helping to improve its environmental health record. One reforested land has produced more than 130,000 carbon credits so far and eventually will generate 1.12 million tons of carbon-offset credits, equivalent to one-fifth of that Class 1’s annual carbon emissions.

100 gallons of diesel fuel = 1 ton of CO2.

5 tons = 1 car

I’m a railroad that consumes 500 million gallons of diesel fuel per year and I have 4,000 operational locomotives, both high horsepower line-of-road and lower horsepower yard units combined. Choosing a very conservative 4 hours per day that each of these locomotives are idling where they could have been shutdown and not negatively impacted operations. Using an average of 3.5 gallons of fuel burned per hour idling per locomotive – some easy math shows an annual consumption of over 20 million gallons of excess idle, which is over 4% of the total annual fuel consumption for that particular Class I railroad – do we have your attention yet? If the price of diesel fuel was $3.50 per gallon, this translates to $40 Million – and that is an annual savings not a one-time savings. That is a lot of fuel and a lot of potential budget impact.

There are 24 Class 2 Railroads in the USA with an average fleet size of 48 locomotives. Using an average of 4 hours per day of idle time, that is 70,000 idling hours annually for the fleet, which equates to 12,250 gallons of fuel used while idling annually. At a price of $3.50 per gallon of diesel equals a yearly savings total of $42,875 utilizing the 3C Telemetry LMU4.

A15% reduction with the use of the LMU4 would equate to $128,625 annually.

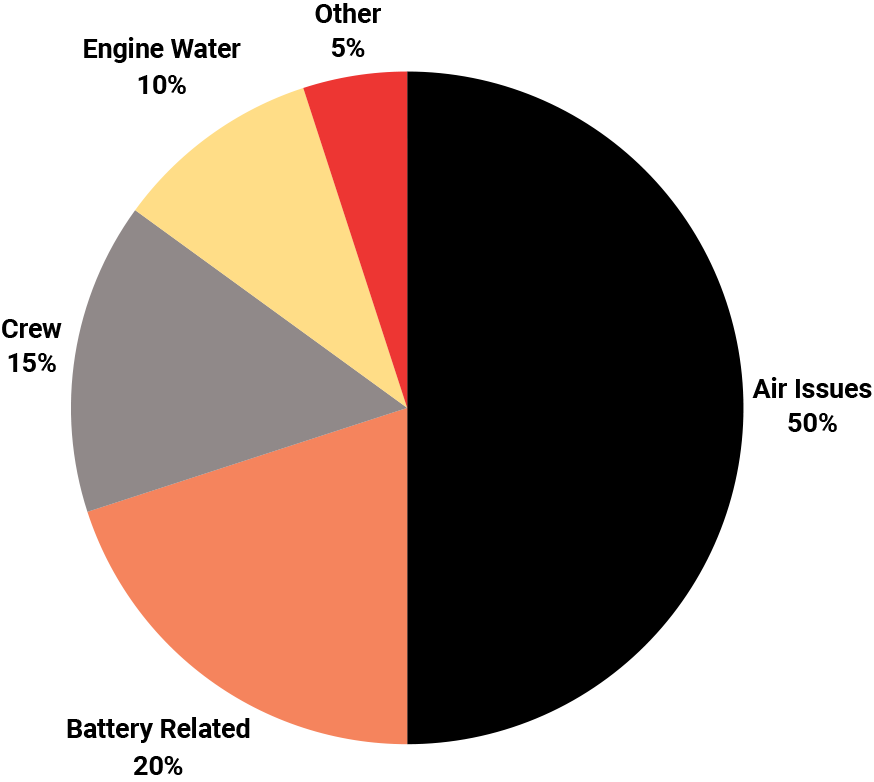

Why Do Locomotives Idle

- Waiting for further instructions, work assignments, or orders

- Need to keep the engine warm to be sure that:

- Water and fuel don't freeze

- Oil doesn't become stiff for cranking

- The engine starts (below 40°F)

- Battery charge is maintained

- Need heating or cooling for their cab

- Provide power for other systems

Stats And Facts:

- Locomotive switchers idling consumes 60 million gallons of diesel fuel annually. (EPA estimate)

- Class I railroads represent the largest number of locomotives in the country. There are about 20,000 Class I locomotive engines and, of this number, about 5,000 are switchers. (EPA estimate).

- The time of maximum carbon accumulation is when locomotives are idling or operating at minimum power output. The time of maximum carbon ejection is when prower is applied after a period of idling. (Railroad Fire Prevention Guide)

- Switchers idle about 60% of total engine operating time - about 2,500 to 3,000 hours per year. (EPA estimate)

- Idling engines will burn 3 to 4 gallons of fuel per hour. (EPA estimate)

Emission reduction has been proven in the locomotive industry with the monitoring and and utilization of idle reduction technology. Emission reductions of 1000's of kg of Particulate Matter (PM) and Green House Gasses (GHG), by 10,000 's kg of NOx and 100's of tons of CO2 have been documented. However, because short-line railroads operate on very limited profit margins, they do not often have the ability to invest in new technology for these purposes. Not any more, with 3C Telemetry's Idle Reduction Monitoring. It is not only affordable for short lines but also powerful. A valuable tool in the industry, where perhaps traditional solutions such as automatic engine start-stop systems (AESS) can be problematic if one of their many components or procedures fail.